Project status

Completed – 10.2019 – 09.2023

Consortium

Friedrich-Alexander Universität Erlangen-Nürnberg (FAU), VDZ gGbmH (VDZ), thyssenkrupp Industrial Solutions AG (TKIS), Lhoist Germany Rheinkalk GmbH (LGE), Dyckerhoff GmbH, SUEZ Recycling Süd GmbH (SUEZ), ESTRA Energy Strategies Ltd (ESTRA), Ulster University (ULSTER), Calix Europe Limited (CALIX), Centre for Research and Technology Hellas (CERTH), CaO Hellas (CH)

Project description

ANICA is a 4-year research project funded by the ACT (Accelerating CCS Technologies) Consortium. The project focuses on developing novel concepts for CO2 capture in lime and cement plants.

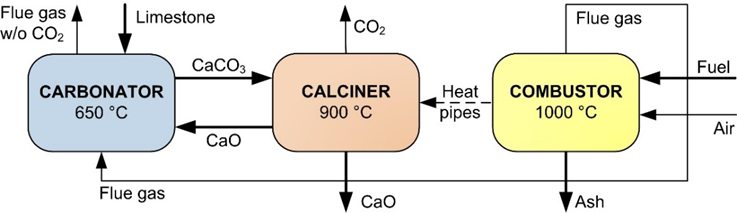

The main innovation is the use of an indirectly heated carbonate looping process (IHCaL) and its integration into lime production plants and cement production plants aiming at lowering the energy penalty and CO2 avoidance costs. Synergies in the IHCaL process and production process of cement and lime are offered, since same solid materials are used in both processes. A sorbent utilization of more than 90% is expected to be achievable with the novel integration of IHCaL process. When combining the utilization of waste derived fuels with a high biogenic fraction with CO2 capture, this novel concept offers a high potential for net negative CO2 emissions.

Main objectives of the project are:

- Demonstration in relevant environment (i.e. TRL 6) by long-term pilot tests at 300 kWth

- Development of 1D- and 3D-models of dual fluidized bed reactors

- Evaluate risks, economic performance, and environmental impact of process

- Provide the basic design and cost estimation of a 2 MWth demonstration plant.