Projektstatus

Aktiv – 01.2024 bis 12.2026

Projektpartner

| Universities |

|

|

| Technology providers |

|

|

| Consultancy company |

|

|

| End users |

|

|

| Research institute |

|

|

Projektbeschreibung

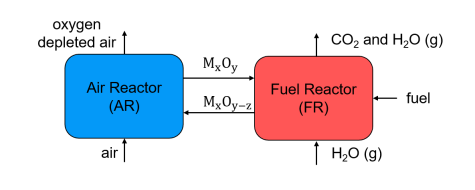

The high cost of CO2 capture is considered as one of the most important barriers to a wider application of Carbon Capture Utilization and Storage (CCUS). This project will develop and demonstrate a technology that is expected to increase capture rate, reduce energy penalty, and improve cost-efficiency of CO2 capture compared to postcombustion capture. Further, when applying fuels with aggressive ash species such as waste-derived fuels and biomass, this technology has the potential to reduce corrosion on heat-transfer surfaces, allow for higher steam temperatures and improve electric efficiency. The technology is Chemical-Looping Combustion (CLC), a promising and flexible future-oriented concept.A schematic description of CLC can be found in the figure below.

CLC has been researched for about two decades. However, it has yet to be properly demonstrated at MW scale for several fuels of high relevance for the future European energy system. Also, the full advantage of CLC with respect to corrosion and material choice has not been examined in detail. The objective of the ACLOUD is to address principally these two topics.

The project will focus on the use of wastederived fuels of relevance in Europe (e.g., recycled waste wood and refuse derived fuels) and low-cost biomass (e.g. forestry and agricultural residues). These are fuels for which competing applications are low on the value chain, and for which the application of CO2 capture and storage is very attractive. This is because it will lead to net-negative CO2 emissions, for maximum climate mitigation benefits.

Applications that will be directly addressed in the project include Waste-to-Energy, Combined Heat and Power, district heating and industries that utilize biomass fuels such as e.g., Pulp Mills. Much of the output will be possible to extrapolate to other fuels and industries as well.

MitarbeiterInnen

| Projektverantwortliche(r) (EST) | Claudia Cremer | Pilot test coordination and evaluation |

| Weitere MitarbeiterInnen | Dennis Hülsbruch | Coordination of corrosion and in-bed measurements during pilot tests, evaluation of pilot tests |

| Philipp Mohn | Consultation |

Weitere Informationen

M.Sc. Claudia Cremer

Contact

claudia.cremer@est.tu-...

work +49 6151 16-23324

Work

L1|01 350

Otto-Berndt-Straße 2

64287

Darmstadt